A carefully considered preventive maintenance program can positivetly impact on various areas of your retail store. If you want to learn how to implement an effective preventive maintenance plan in your retail store, keep reading.

The most successful preventive maintenance programs take a multi-faceted approach to address potential performance and quality issues even before they occur, resulting in 30% to 40% savings compared to corrective maintenance.

The goal of preventive maintenance in retail is to keep equipment and computer programs operating by performing maintenance work on them before failures and defects manifest. It’s a term used for maintenance work on machines, equipment, and systems in general, but in recent years, it has been often used in IT-related areas such as networks and software, essential for the smooth functioning of a retail store.

Periodic checks of the equipment are carried out according to a maintenance schedule and are based on regular maintenance tasks such as periodic replacement of wearing parts, lubrication, software updates, and backups.

10 Tips to Implement an Effective Preventive Maintenance Plan in Your Retail Store:

Here are 10 tips for implementing an effective preventive maintenance (PM) plan in your retail store that can help you avoid unplanned downtime due to equipment failure:

1. Evaluate the Current State

Conducting a baseline assessment of your facilities and equipment before starting any new maintenance program. This will give you a broad view of your facilities and help guide your actions and decisions.

Consider the quantity of equipment and furniture, their age and type, the original equipment manufacturer of the machines, the entire production chain within the store, the level of automation, and any noteworthy historical maintenance issues, whether unique or recurring.

Once you’ve considered the overall picture, weigh the pros and cons of your equipment’s current state and decide where you want to improve maintenance and performance.

2. Review Manufacturer Specifications

After evaluating your equipment and machinery, it’s time to start researching. This may not be the most satisfying part of the process, as you might not see the immediate results of your preventive maintenance plan, but it’s an essential step to get there.

Manufacturer documents and specifications can help determine the best-recommended maintenance practices for your equipment, which will be a crucial part of the plan you develop.

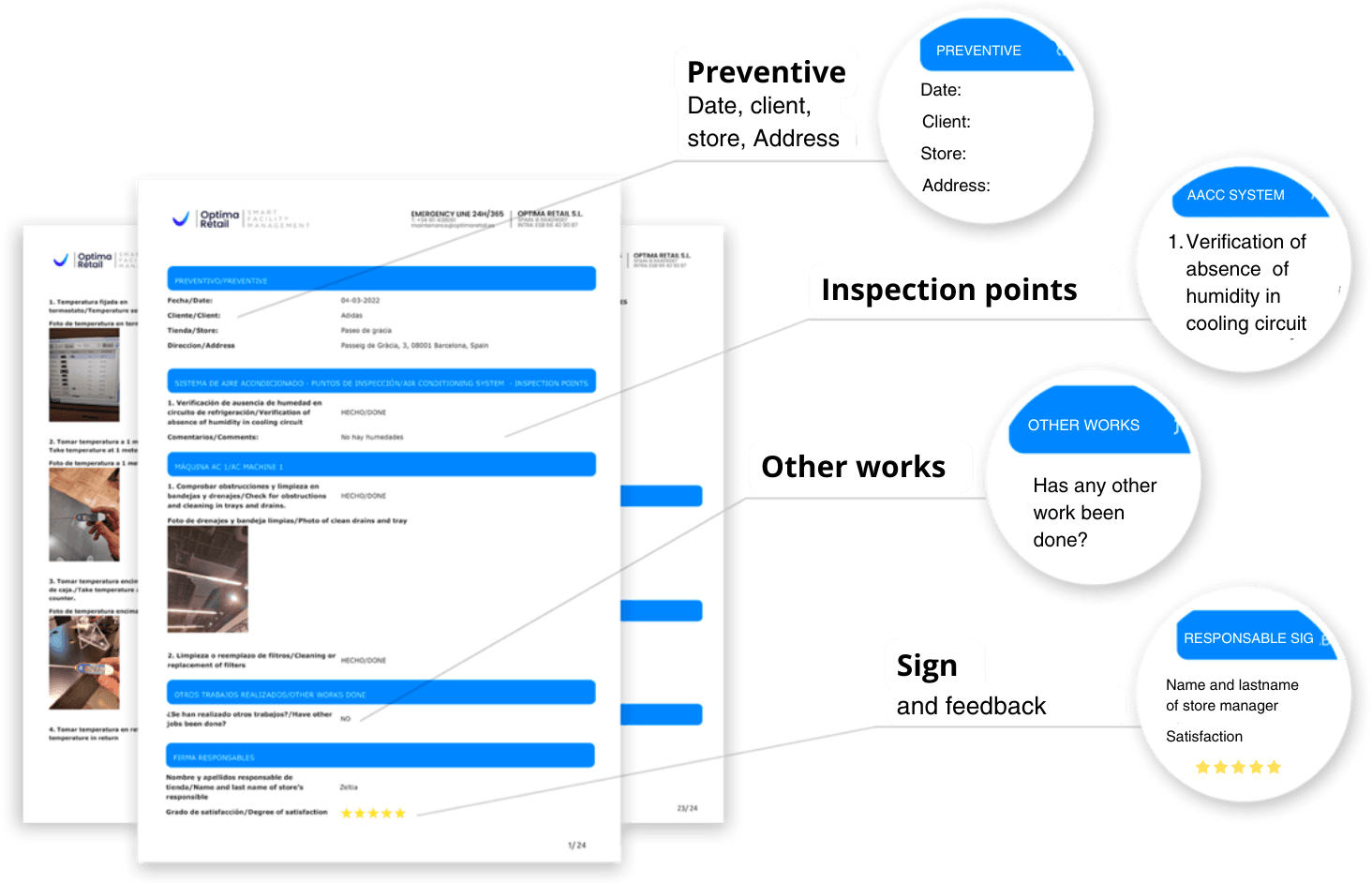

3. Documentation is Key

Documentation is an essential part of any good maintenance program. You’ll generally want to document as much as possible, including the current state of equipment, the newly created maintenance plan, and the actions taken to achieve it.

Comprehensive documentation serves several purposes when developing a preventive maintenance plan:

- Helps you keep track of the work done so far

- Creates a reliable single source for the maintenance practices you’ve developed

- Allows employees to access and easily review the plans.

4. Seek Support

Preventive maintenance sometimes has a bad reputation among facility owners and employees. It may be seen as a practice that reduces productivity, increases unnecessary downtime, and generates additional work.

Communicate to your staff that preventive maintenance is a key aspect of their job and an important factor in the success of your facility, as it actually increases overall productivity by 5% to 10% and reduces more costly reactive maintenance.

5. Set Goals and Benchmarks

Based on the overall assessment you conducted, it’s highly beneficial to set goals for uptime, productivity, and quality. Regularly comparing incremental improvements to your starting point can motivate both you and your employees as they see the results of their efforts.

6. Take a “Snapshot”

For the purposes described above, it can be helpful to take a figurative snapshot of the initial performance metrics of your facility as you embark on a new maintenance program. This makes it easier for you and your employees to review this data and allows them to focus more on the results.

7. Track Progress

While your goals and benchmarks might have one, three, and five-year plans, you should also ensure that you can see more incremental results. If you have something at hand, make sure to review it regularly, celebrating the improvements that occur monthly.

8. Investigate Technical Scenarios

Performance data tracking and automation tools are more powerful and ubiquitous than ever; 47% of global manufacturers use predictive maintenance technologies. Even if you’re not interested in acquiring and installing new sensors and other equipment, you can take steps to use your existing CMMS data in a more analytical way.

9. Inspect and Modify as Needed

Your first, second, or third preventive maintenance program should not be the last. If something in the plan isn’t working, don’t hesitate to change it. Continuous improvements won’t happen if you don’t have backup data for modification.

With these tips in mind, you can now feel more confident in implementing an effective preventive maintenance plan in your retail store.

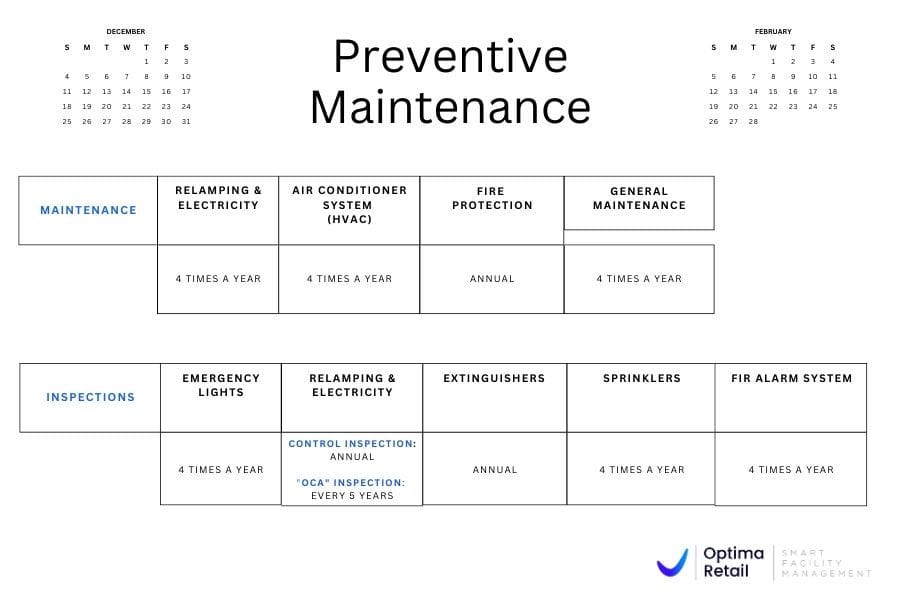

10. Mantente actualizado en materia de normativa

Below is a brief guide to the minimum preventive maintenance required in Spain that should be performed in your store to ensure compliance with regulations and the smooth functioning of the facility.